A solar Concentrated Solar Power (CSP) plant is a plant that uses the concentrated solar radiation through a system of mirrors to produce high temperature steam.

Unlike solar systems using photovoltaic technology, Solar energy can be stored in the form of heat during the day and used to produce electricity through steam turbines even outside of the hours of maximum insolation .

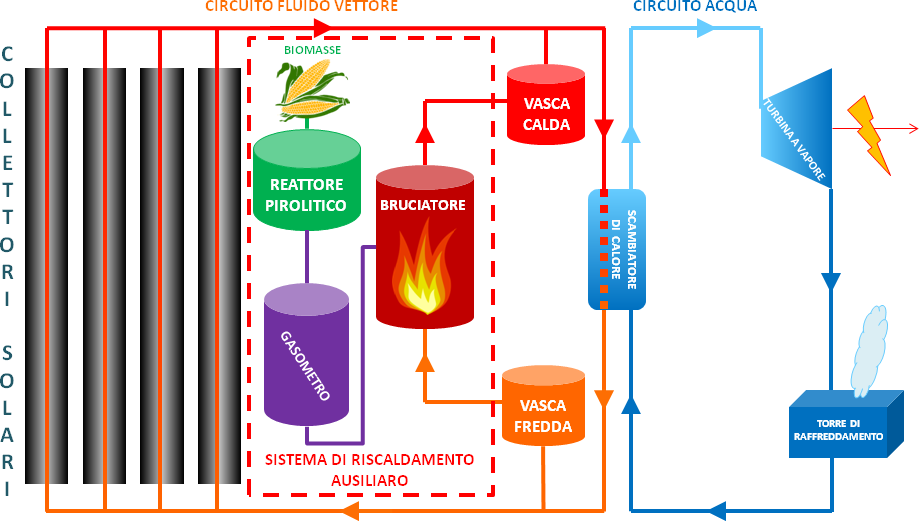

The mirrors concentrate the solar energy in a pipe traversed by a high heat capacity fluid, can reach operating temperatures of from 400°C to 550°C. The carrier fluid is collected in heated storage tanks , from where it is taken gradually to heat water up to transform it into steam . The steam at high temperature and pressure is then swirled, producing electricity sold to the grid. The carrier fluid removed and reduced in temperature up to 250°C then enters again into the circulation to be heated by solar radiation.

Increasing the extension of the system of solar collectors and mirrors increases the thermal energy stored , and then the hours of operation of the system. In order to extend the operation of the system even at night you can install a burner fueled by biomass, biogas or possibly from conventional sources, able to raise the temperature of the carrier fluid present in the sewage. The system can also be exploited to produce thermal energy for industrial or district heating.

For the realization of solar thermal plants, or Concentrating Solar Power (CSP), can be used different types of mirrors such as solar towers , parabolic dishes , parabolic trough or Fresnel mirrors . Furthermore , the carrier fluid can be varied, such as diathermic oil, molten salt or water.

The group Future Energy identifies opportunities for each individual the most efficient technology, also depending on the conditions of the installation site and as a result of weather and climate assessments of solar radiation, with the application of numerical simulation models in order to dimension all plant components . It also studied the application of all the auxiliary equipment for the proper functioning of the system for remote monitoring and management in the life cycle of the system in the field of Operation & Maintenance and Asset Management.

Born in the United States between 1980 and 1990 , the technology has seen the first applications in Europe since 2000 in Spain with technology diathermic oil and Italy with molten salt technology . The technology is having a rapid increase in recent years and as the ratio of ENEA estimated to reach 5% of installed capacity worldwide by 2030 and 10% by 2050. (ENEA CSP Study in italian)

TECHNOLOGY MADE IN ITALY: MOLTEN SALT CSP

The group Future Energy proposes, designs and installs, where possible, the molten salt technology. It is a technology "Made in Italy", which uses a mixture of sodium and potassium nitrates as the carrier fluid, with operating temperature between 290 ° C and 550 ° C.

The molten salt technology is applicable both in the presence of linear parabolic mirrors than Fresnel lenses and allows, thanks to the high thermal capacity to reduce the size of the plant. The mixture of molten salts, in addition to the high heat capacity and density, allows to work in greater safety conditions being non-flammable and non-toxic and working with lower pressures. Also it is a compound not polluting, ensuring a more simple disposal at the end of the life cycle within the plant.

The molten salt technology with linear parabolic mirrors has been operational since 2010, with the inauguration of the plant called "Archimede" power of 5MW in Priolo Gargallo in the Syracuse area managed by ENEA.

CASE STUDY: MOLTEN SALT CSP IN CENTRAL ITALY

In the context of use for the production of heat and electricity on a plot of 30 hectares in the center of Italy, the group Future Energy has identified in the solution thermodynamic solar molten salt parabolic trough collectors with the most efficient and less impact for preparing project the realization of the plant.

In the specific case the technology of solar thermodynamic molten salt allows the exploitation of the installation site, characterized by a global radiation of 1625 kWh/m2 and a direct radiation equal to 1850 kWh/m2. The molten salt CSP plant, which provides a solar multiplier of 2.5 and will see over 20km of installed solar collectors with a heat input greater than 40MW captured. The plant will be capable of generating an electrical output of approximately 6MW with an average annual production of approximately 20,300,000 kWh equal to the consumption of about 7,000 families, saving 13,000 tons of CO2 per year. The system also allows to transfer the thermal energy output from the turbines for industrial purposes or district heating.